Adaptive Environment Simulation

and Test Control

Introduction

An environmental simulation and test is used

to determine a product's ability to perform during or

after exposure to a specific environment. These tests

are often used to prove product integrity, verify operational

limits, determine warranty terms, and prepare procedures

for safe operations.

CyboSoft offers an innovative Model-Free

Adaptive (MFA) control solution for controlling

environmental test equipment without having to tune

controller parameters. Climatic chambers, rapid thermal

processing (RTP) chambers, wind tunnels, dynamic simulation

and testing apparatus all have critical control loops.

The MFA controllers can tightly control these critical

loops and can adapt to new test conditions so that tedious

and costly manual tuning of controller parameters can

be avoided.

Solution

Why is Environment Test Control Difficult?

Components and products may be used in different

environments during their lifetime. To ensure their

operability in severe conditions, simulation of environmental

conditions ranging from high temperature and humidity

to a cold and dry atmosphere might be required. Components

and systems requiring environmental testing include

engines, turbines, compressors, motion systems, vehicles,

aircraft, aerospace materials, semiconductor equipment,

mechanical systems, and robotics.

Since environmental tests require establishing certain

stable test conditions, an automatic control system

to control all critical process variables is important.

However, when the environmental conditions vary from

test to test, the process dynamics may vary significantly.

If PID controllers are used, frequent manual tuning

of controller parameters is required, resulting in low

efficiency and a waste of time and resources.

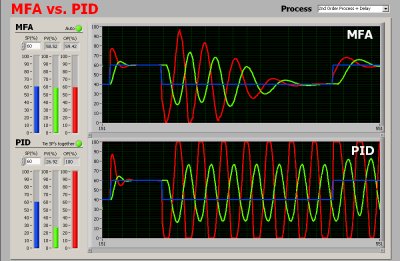

MFA Controller vs. PID Controller

The following trends shown demonstrate MFA

(top) and PID (bottom) controllers are controlling 2

identical second order processes. As we begin, both

are controlling well. Then, we change the processes

to second order plus delay processes. Due to the large

delay time, both control systems start to oscillate,

but the MFA is able to quickly adapt to provide good

control, while the PID will continue to oscillate. When

the setpoint is changed again, there is no oscillation

and MFA continues to provide good control.

This demonstration shows the adaptive capability of

a SISO

(single-input-single-output) MFA controller that is

ideal for environmental simulation and test control.

Summary

MFA controllers are ideal for environmental

simulation and test control. Avoiding process models

means lower development costs and faster time to market,

more robust and precise control means better lab test

results, and no manual tuning means lower operating

costs and longer up time.

This general-purpose, powerful solution can be easily

implemented. No special knowledge or experience with

advanced control or process modeling is required. Tedious

manual tuning of controllers can be eliminated allowing

the user to focus on R&D, design, proto-typing,

and testing.

• View

controller video 1.6MB

( Macromedia

Shockwave plug-in required )

|