Model-Free Adaptive (MFA)

Control

Concept and Significance of Model-Free Adaptive

Control

A Model-Free Adaptive control system has the following

properties or features:

• No precise quantitative knowledge of the process

is available;

• No process identification mechanism or identifier

is included in the system;

• No controller design for a specific process

is needed;

• No complicated manual tuning of controller parameters

is required; and

• Stability analysis criteria are available to

guarantee the closed-loop system stability.

The essence of MFA control is described with discussions

relating to combustion process control on the following

five issues:

Process Knowledge Issue

Most advanced control methods are based on a good understanding

of the process and its environment. Laplace transfer

functions or differential equations are used to represent

the process dynamics. In many process control applications,

however, the dynamics may be too complex or the physical

process is not well understood. Quantitative knowledge

of the process is then not available. This is called

a “black box” problem.

In many cases, we may have some knowledge of the process

but are not sure if the knowledge is accurate or not.

In process control including combustion control applications,

we often deal with raw materials, wild inflows, changing

fuel type and heating values, unpredictable downstream

demand changes, and frequent switches of product size,

recipe, batch, and loads. These all lead to a common

problem: that is, we are not sure if the process knowledge

is accurate or not. This is called a “gray box”

problem.

If quantitative knowledge of the process is available,

we have a “white box” to deal with. It is

a relatively simple task to design a controller for

the process in this case because we can use well-established

control methods and tools.

Although Model-Free Adaptive control can actually deal

with black, gray, and white box problems, it is more

suitable to deal with the gray box problem. Most industrial

processes are gray boxes.

Process Identification Issue

For traditional adaptive control methods, if the quantitative

knowledge of the process is not available, an on-line

or off-line identifier is required to obtain the process

dynamics. This contributes to a number of fundamental

problems:

• the headache of off-line training that might

be required,

• the tradeoff between the persistent excitation

of signals for correct identification and the steady

system response for control performance,

• the model convergence and local minimum problems,

and

• the system stability issues.

The main reason that identification-based control methods

are not well suited to process control is that control

and identification are always in conflict. Good control

will lead to a steady state where setpoint (SP), controller

output (OP), and process variable (PV) will show straight

lines on a trend chart. Since any stable system can

reach a steady state where process dynamic changes cannot

be seen, good identification may require insertion of

test signals. This requirement is not easily accepted

by plant operators.

MFA control avoids the fundamental problems by not using

any identification mechanism in the system. Once an

MFA controller is launched, it will take over control

immediately. The MFA algorithms used to update the weighting

factors are based on a sole objective, which is to minimize

the error between SP and PV. That means, when the process

is in a steady state where error is close to zero, there

is no need to update the MFA weighting factors.

Controller Design Issue

The main reason PID is still popular is that it is a

general-purpose controller that does not require controller

design procedures. Designing a controller for a specific

application requires special expertise. Since most advanced

controllers are model-based, they cannot be a general-purpose

controller. Thus, they are not widely used in process

control, although these methods have been developed

for 30 to 40 years.

MFA controllers are general-purpose controllers. A number

of MFA controllers have been developed to control a

variety of problematic industrial loops. Examples include

SISO MFA to replace PID and requires no manual tuning,

Nonlinear MFA to control extremely nonlinear processes,

Anti-delay MFA to control processes with large time

delays; MIMO MFA to control multivariable processes;

Feedforward MFA to deal with large measurable disturbances;

and Robust MFA to force the process variable to stay

within defined bounds.

For an MFA controller user, there are no controller

design procedures required. One can simply select the

appropriate controller as its name suggests, configure

the controller with certain parameters and launch the

MFA controller. This is one of the major differences

between a Model-Free Adaptive controller and other model-based

advanced controllers.

Controller Parameter Tuning Issue

An adaptive controller should not need to be manually

tuned. This is also true for MFA controllers. MFA can

adapt to new operating conditions due to changes in

process dynamics, loads, or disturbances, and there

is no manual tuning required. As a user-friendly feature,

certain parameters are available to allow the user to

quickly adjust the control performance.

System Stability Issue

Control system stability analysis is always an important

issue because it determines if the controller will be

useful in practice. When the system stability criterion

is available, one can use the criterion to decide if

the control system can be safely put in operation. As

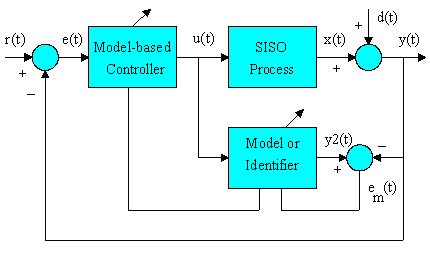

shown in Figure 1, a model-based self-tuning adaptive

control system has 3 major components: controller, process,

and model. Here, the model refers to a mathematical representation

describing the relationship between the process input

and output. The model is usually built by an identifier

that has a learning algorithm to minimize the model

error em(t) (the difference between PV and model output

y2(t) ) using the process input and output data.

|

Signals:

r(t) – Setpoint

u(t) – Controller Output

y(t) – Process Variable

x(t) – Process Output

d(t) – Disturbances

e(t) – Error

e(t) = r(t) - y(t).

y2(t) – Model Output

em(t) – Model Error

em(t) = y2(t) - y(t).

|

Figure 1. Model-Based Adaptive

Control System

Then, the stability of the overall closed-loop

control system is related to the process, the controller,

and the model in the following way:

• stability of the process is assumed (i.e.,

the process is open-loop stable);

• stability of the control loop must be guaranteed

by the convergence of the model; but

• convergence of the model is dependent on the

stability and persistent excitation of signals originating

from the control loop.

This is a circular argument that it is difficult to

resolve. Thus, there is no general stability criterion

available for a model-based adaptive control system.

In other words, each time a model-based adaptive controller

is used in a control system, its stability has to

be analyzed. This is certainly a major technical barrier

in applying model-based adaptive control methods.

In contrast, since MFA does not have an identifier,

a general system stability criterion is developed.

That is, if the process is passive (a process that

does not generate energy or heat by itself), the closed-loop

MFA control system stability is guaranteed, and the

process can be linear/nonlinear, time invariant/time-varying,

etc. A combustion process is a passive process since

the heat it generates has to come from burning fuel

from outside of the process.

Single-Loop MFA Control System Structure

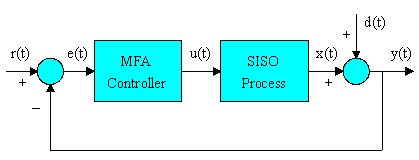

The system structure of a single-input-single-output

(SISO) MFA control system is shown in Figure 2. The

structure is as simple as a traditional single-loop

control system that includes a SISO process, a SISO

MFA controller, and a feedback loop.

|

Signals:

r(t) – Setpoint, SP

u(t) – Controller Output, OP

y(t) – Process Variable, PV

x(t) – Process Output

d(t) – Disturbances

e(t) – Error, e(t)=r(t)-y(t).

|

Figure 2. Single-Loop MFA Control System

Control Objective

The control objective for the controller is to produce

an output u(t) to force the process variable y(t)

to track the given trajectory of its setpoint r(t)

under variations of setpoint, disturbances, and process

dynamics. In other words, the task of the MFA controller

is to minimize the error e(t) in an online fashion.

The minimization of e(t) is achieved by (i) the regulatory

control capability of the MFA controller, and (ii)

the adjustment of the MFA controller weighting factors

that allow the controller to deal with process dynamic

changes, disturbances, and other uncertainties.

Compared to Figure 1, the MFA system does not have

a process model or identifier. Thus, no model error

em(t) needs to be minimized and only the error e(t)

between the setpoint (r(t) or SP) and process variable

(y(t) or PV) needs to be minimized.

MFA Controller Architecture

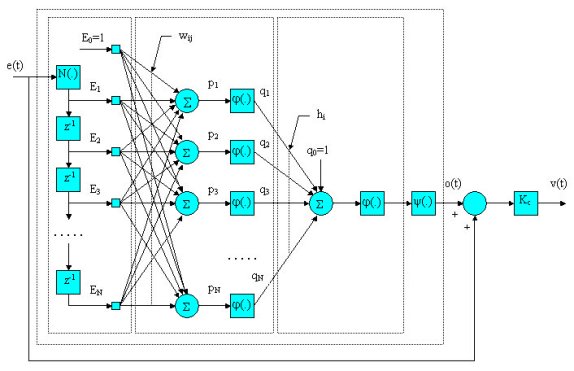

Figure 3 illustrates the core architec¬ture of

a SISO MFA controller. Used as a key component, a

multilayer perceptron neural network consists of one

input layer, one hidden layer with N neurons, and

one output layer with one neuron.

Within the neural network there is a group of weighting

factors (wij and hi) that can be updated as needed

to vary the behavior of the controller. The algorithm

for updating the weighting factors is based on the

goal of minimizing the error e(t). Since this effort

is the same as the control objective, the adaptation

of the weighting factors can assist the controller

in minimizing the error while process dynamics are

changing.

Figure 3. Architecture of a SISO MFA controller

Also, the neural network based MFA controller

“remembers” a portion of the process data

providing valuable information for the process dynamics.

In comparison, a digital version of the PID remembers

only the current and previous two samples. In this

regard, PID has almost no memory, and MFA possesses

the memory that is essential to a “smart”

controller.

MFA Control System Requirements

As a feedback control system, MFA requires that the

process be

• controllable,

• open-loop stable, and

• either direct or reverse acting (process does

not change signs).

If the process is not controllable, improvement of

the process structure or its variable pairing is required.

If the process is not open-loop stable, it is always

a good practice to stabilize it first. However, for

certain simple open-loop unstable processes such as

a non self-regulating level loop, no special treatment

is required when using MFA.

If a process changes its sign within its operating

range, special MFA controllers are required. MFA controllers

can be easily configured with only a few parameters.

|