Multivariable MFA

Control System

In control applications, most processes have multiple

inputs and multiple outputs with interactions in between.

The level and density loops of an evaporator, and the

temperature loops of a multi-zoned furnace are good

examples of multivariable processes. Lacking general-purpose

multivariable controllers, a large percentage of multivariable

processes are treated as single variable processes resulting

in poor control, wasted energy and materials, inconsistent

quality, and plant upsets.

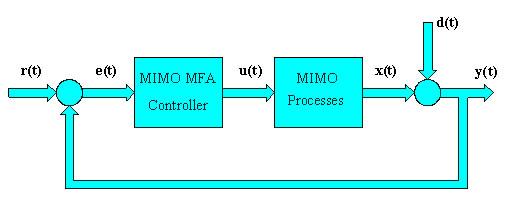

This graph illustrates a multivariable Model-Free Adaptive

(MFA) control system, which consists of a multi-input

multi-output (MIMO) process and an MIMO MFA controller.

Multivariable MFA control system

Similar to a SISO system, the MIMO system has controller

setpoints r(t), error signals e(t),

controller outputs u(t), process variables

y(t), and disturbance signals d(t).

Since it is a multivariable system, all the signals

here are vectors represented in bold case.

2-Input-2-Output MFA Control System

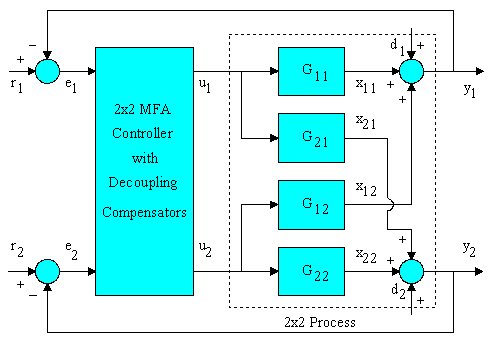

Without losing generality, we will show how a MIMO MFA

controller works with a 2-input-2-output (2x2) system

as illustrated in following graph. In the 2x2 MFA system,

the 2x2 MFA controller consists of two main controllers

C11, C22, and two compensators C21, and C12. The process

has four sub-processes G11, G21, G12, and G22.

2-input-2-output MFA control system

The measured process variables y1 and y2 are used

as the feedback signals for the main control loops.

They are compared with the setpoints r1 and r2 to produce

errors e1 and e2. The output of each controller associated

with one of the inputs e1 or e2 is combined with the

output of the compensator associated with the other

input to produce control signals u1 and u2. The output

of each sub-process is cross-added to produce measured

process variables y1 and y2. Notice that in real applications

the outputs from the sub-processes are not measurable

and only their combined signals y1 and y2 can be measured.

Thus, by the nature of the 2x2 process, the inputs u1

and u2 to the process are interconnected with outputs

y1 and y2. The change in one input will cause both outputs

to change.

The control objective for this 2x2 MFA control system

is to produce control outputs u1(t) and u2(t) to force

the process variables y1(t) and y2(t) to track their

setpoints r1(t) and r2(t), respectively. The minimization

of e1(t) and e2(t) is achieved by (i) the regulatory

control capability of the MFA controllers, (ii) the

decoupling capability of the MFA compensators, and (iii)

the adjustment of the MFA weighting factors that allow

the controllers to deal with the dynamic changes, large

disturbances, and other uncertainties.

2x2 MFA Controller Configuration

A 2x2 MFA controller can be considered to have 2 main

controllers C11 and C22. For each main controller, the

parameters to configure are: (1) Sample Interval, Ts

- the interval between two samples or calculations in

seconds. A high speed MFA controller can run at a 1

millisecond rate; (2) Controller Gain, Kc1 - use of

a default value is recommended, (3) Time Constant, Tc

- a rough estimate of the process Time Constant in seconds;

(4) Acting Type - direct or reverse acting of the process;

and (5) Compensator Gain, Kc2 - to deal with the interaction

from the other loop.

MIMO MFA Controller Application Guide

A MIMO system can be much more complex than a SISO system,

therefore precautious must be taken when applying a

MIMO MFA controller. When designing a multivariable

control system, the first step is to decide which process

variable is paired with a manipulated variable. A MIMO

MFA control system should follow these pairing rules:

(1) Each main process (G11, G22) has to be controllable,

open-loop stable, and either reverse or direct acting;

(2) A process with a large static gain should be included

in the main loop as the main process (G11, G22), and

a process with a small static gain should be treated

as a sub-process. (G21, G12); (3) A faster process should

be paired as the main process, and a slower process

or processes with time delays should be treated as sub-processes;

and (4) If Pairing Rules 2 and 3 are in conflict, a

tradeoff is the only option.

As a general guide, an MFA control system should be

designed based on the degree of interactions between

the loops. This table lists the control system design

strategy based on the degree of interaction of a MIMO

process.

MFA control system design strategy

|

Interaction Measure |

Control

Strategy |

| Small to non interaction |

Tighten both loops with SISO MFA. |

| Moderate interaction |

Tighten important loops with SISO MFA and de-tune

less important loops; or Use MIMO MFA for better

overall control. |

| Severe interaction |

Use MIMO MFA to control the process. May need

to de-tune less important loops. |

|